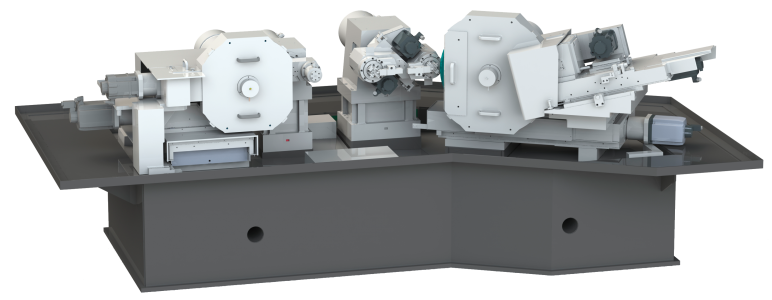

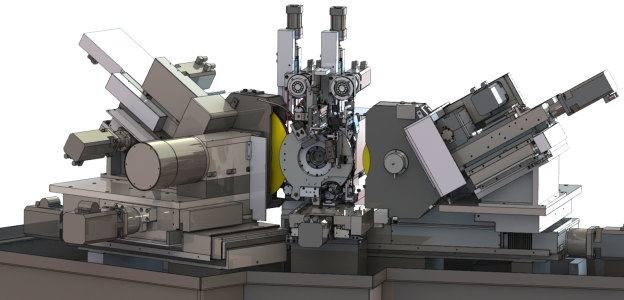

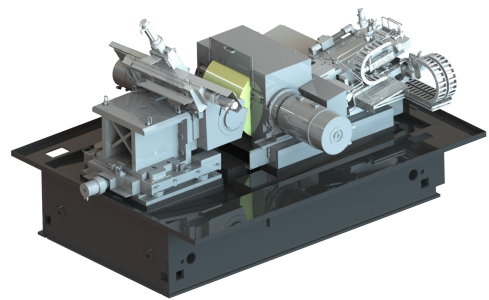

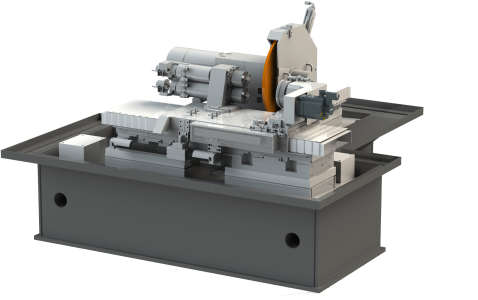

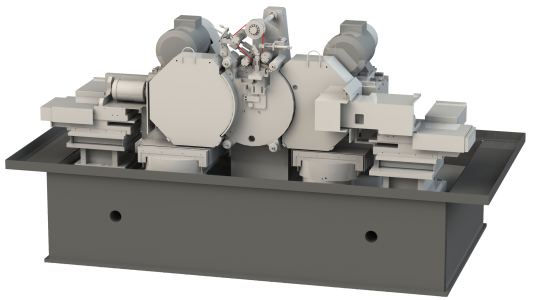

We develop, build and supply grinding machines for leading international customers in the European market - automotive suppliers and rolling bearing industry, construction machinery and manufacturers in the consumer industry.

We are a family business and proud of almost 100 years of know-how. With heart and soul and flexibility at the same time, we develop together with you exactly the optimally adapted solution for your production. Consulting, know-how and service included. MODLER stands for high-precision and ultra-precise results in mass production. Get the best out of your products with our knowledge.